Specifications

Tip Types & Machining

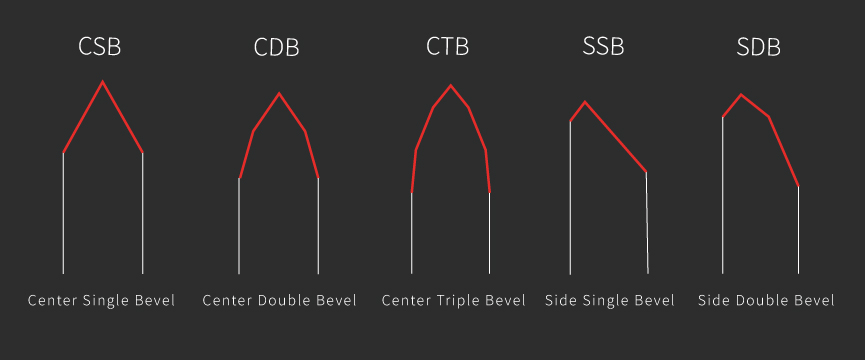

Blade Edge Shapes

Various blade edge designs offer different tip positions and edge lengths to meet diverse cutting needs. Each profile is precisely engineered to match user preferences, enhancing cutting accuracy and stability for a smoother, more efficient experience.

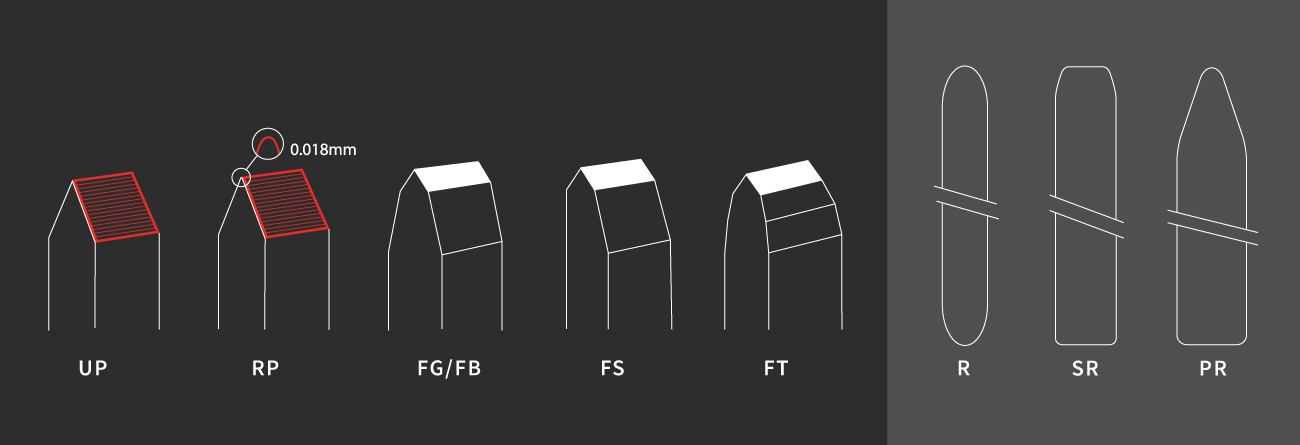

Various blade tip processing and creasing types across different series

KAMURA, with its diverse precision machining technologies, continuously develops and introduces various blade tip designs to meet the diverse needs of different industries.Whether for everyday consumer products or the stringent demands of high-tech industries requiring extreme precision and quality, KAMURA provides the most suitable blades to ensure the best cutting experience for every user.

KAMURA focuses on innovative research and development, precisely adjusting blade tip shapes, bevels, sharpness, and durability through various manufacturing and processing techniques to meet the needs of different materials and applications. For general-purpose tools, emphasis is placed on durability and cost-effectiveness, while products for high-end manufacturing prioritize extreme sharpness and stable precision. This flexible design and manufacturing capability have made KAMURA's tools highly regarded in the market, widely used in food processing, industrial manufacturing, electronics technology, and more.

The scoring is renowned for its exceptional precision tolerance, with production units measured to 0.01 millimeters, breaking the limits of conventional scoring.

This allows users who demand "perfect accuracy" to find an ideal solution.

In the future, KAMURA will continue to refine its technology and expand its product line, dedicated to providing global customers with more efficient and durable cutting tool solutions.

Whether for everyday use or cutting-edge industries, we ensure exceptional cutting tools and outstanding user experiences.