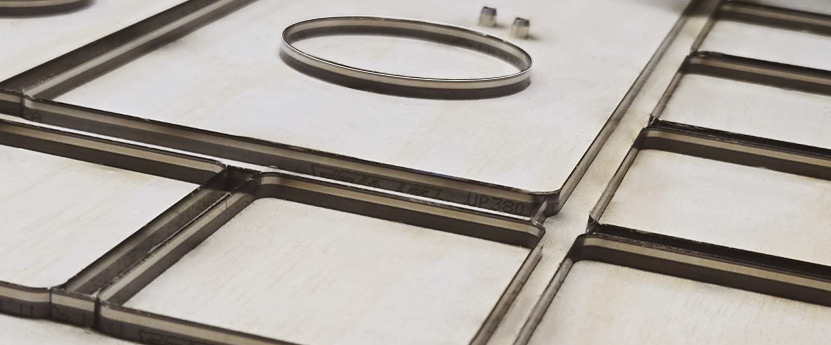

Wood-Die

Origin of Die-Cutting Blades

Wood Die:

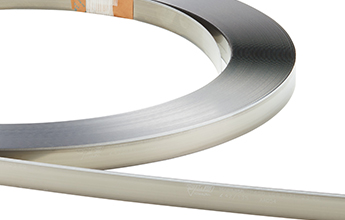

Die-Cutting Blade:

This is the core component, typically made of high-carbon or alloy steel. Its height, angle, and sharpness are selected based on the material being cut to ensure clean and precise results.

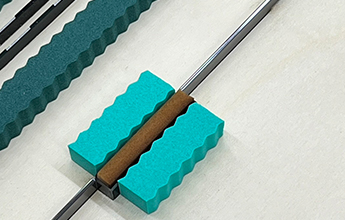

Ejection Rubber:

Ejection rubber stabilizes materials during cutting, prevents misalignment, and improves speed and efficiency.

Creasing :

Punching :

The punching function on die-cutting tools is primarily used to create holes in materials. These holes can serve decorative, functional, or processing purposes. The design and configuration of the punching feature are adjusted according to different application scenarios to meet specific needs.