Case-Studies

Solving Paper Cracking Issues in Die-Creasing: 7 Root Causes & Fixes

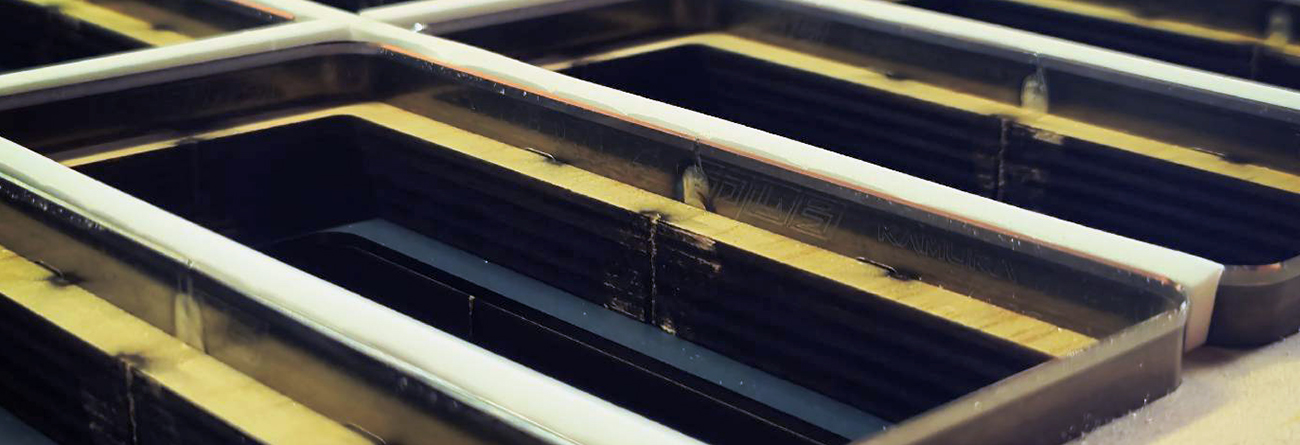

A packaging converter reported that their end customer experienced paper cracking at the crease lines

when using die-cut products made with scoring R- creasing rules. The material used was relatively thin and had a fragile fiber structure,

resulting in a higher defect rate and disruption during the folding and packaging process.

Leveraging our extensive industry experience, we worked closely with the die maker and creasing process partner to investigate the issue.

Through joint analysis, we identified seven key factors that may contribute to paper cracking at the score lines:

1. Dry climate conditions causing the paper to become brittle

2. Overheating during hot-air drying in production

3. Excessive K-rule height, leading to over-creasing

4. Paper made with short fibers, which have poor compressive strength

5. Dull rule tip or insufficient clearance between rule and matrix

6. Uneven die-cutting machine base or platen surface

7. Improper operator setup or pressure adjustment