Sandwich-Die

Sandwich-Die

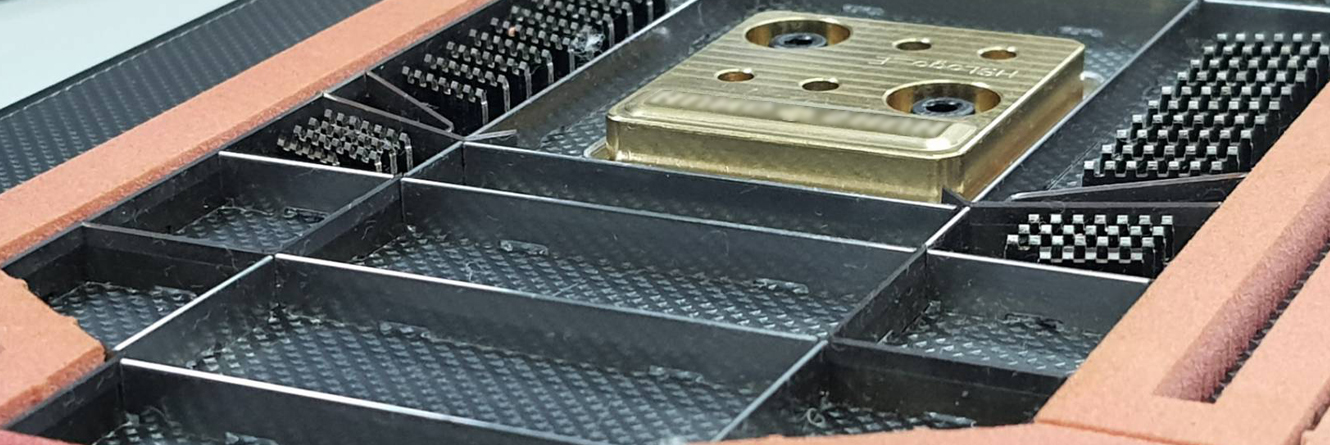

The Sandwich Die is a die-cutting tool with a unique structure, typically composed of multiple layers of materials,

including top and bottom die layers with an intermediate cushion layer, forming a sandwich-like structure.

Main Structure of the Sandwich Die

1. Upper Die (Top Plate)

- Made of metal sheets or hard synthetic materials, it primarily supports and secures the blade.

- Precise cutting and installation design ensure the stability of the blade's position, preventing misalignment.

2. Intermediate Layer (Spacer/Support Layer)

-

-

Elastic materials may also be used to reduce blade deformation under pressure and enhance die-cutting stability.

-

The middle layer can be customized for die-cutting needs, such as local reinforcement or pressure reduction, to suit different material cutting requirements.

3.Lower Die Plate (Bottom Plate)

-

Similar to the upper die plate, its main function is to secure the blade and provide corresponding support.

-

This layer may also include elastic pads or special structures to reduce impact on the material being die-cut, preventing deformation.

The advantages of Sandwich Die include :

1. Improved Die-Cutting Precision

-

Due to its sandwich design, it effectively stabilizes the blade, reducing blade movement and enhancing die-cutting accuracy.

-

Ideal for applications requiring high precision die-cutting, such as electronic products, medical devices, and optical films.

2. Extended Die-Life

-

The sandwich die structure helps evenly distribute cutting pressure, reducing blade wear and deformation.

-

Avoids excessive pressure on a single blade, improving overall durability.

3. Compatible with a wide range of materials

-

Suitable for die-cutting various materials such as foam, double-sided tape, PET, PVC, copper foil, and aluminum foil.

-

Especially suitable for die-cutting precision films and multilayer materials, ensuring accurate cutting of each layer.

4. Enhances production efficiency

-

With better blade stability, it reduces rework caused by precision issues, improving overall production yield.

-

The layered structure reduces the pressure required on the machine, enhancing die-cutting stability and speed.

5. Reduces die-cutting dust and burrs

-

Even blade pressure reduces burrs and dust caused by uneven material stress, making it ideal for high-precision applications.

-

Improve the quality of die-cut products and reduce post-processing costs.

6. Easy to Replace and Maintain

-

Some sandwich die designs allow for blade or internal structure replacement, reducing maintenance costs.

-

The blade configuration can be adjusted based on different die-cutting needs, enhancing the flexibility of the die.