Fine Bending FB series

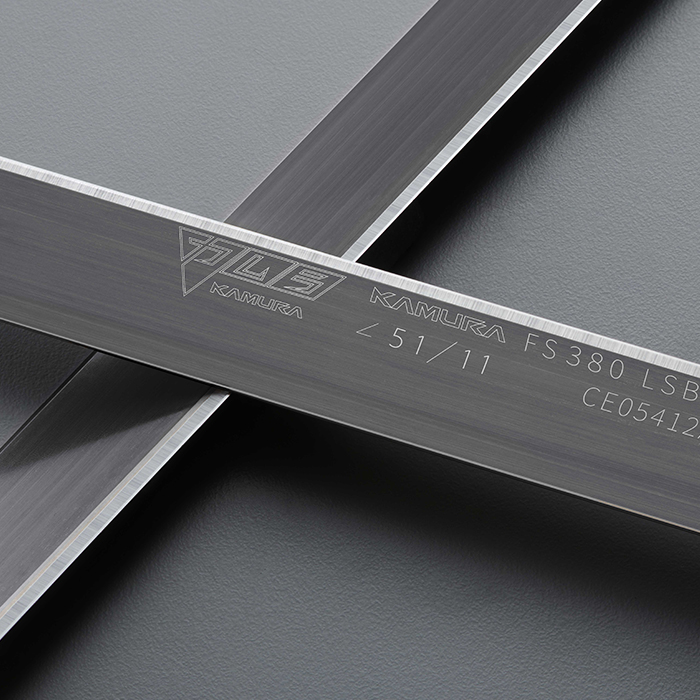

By combining the sharpness and smoothness of precision-ground blade tips with specially treated steel, the bending strength of die-cutting blades is significantly improved—especially when used with high-hardness blade bodies. Precision grinding minimizes micro-defects along the cutting edge, resulting in smoother cuts and reduced edge burrs, ultimately enhancing overall product quality.

The specially treated steel not only increases blade flexibility but also reduces the risk of fatigue fractures during prolonged use. This design is particularly effective for high-strength die-cutting and bending applications, such as plastic films and composite materials. With optimized blade characteristics, cutting stability and efficiency are greatly improved, meeting the demands of high-standard manufacturing processes.

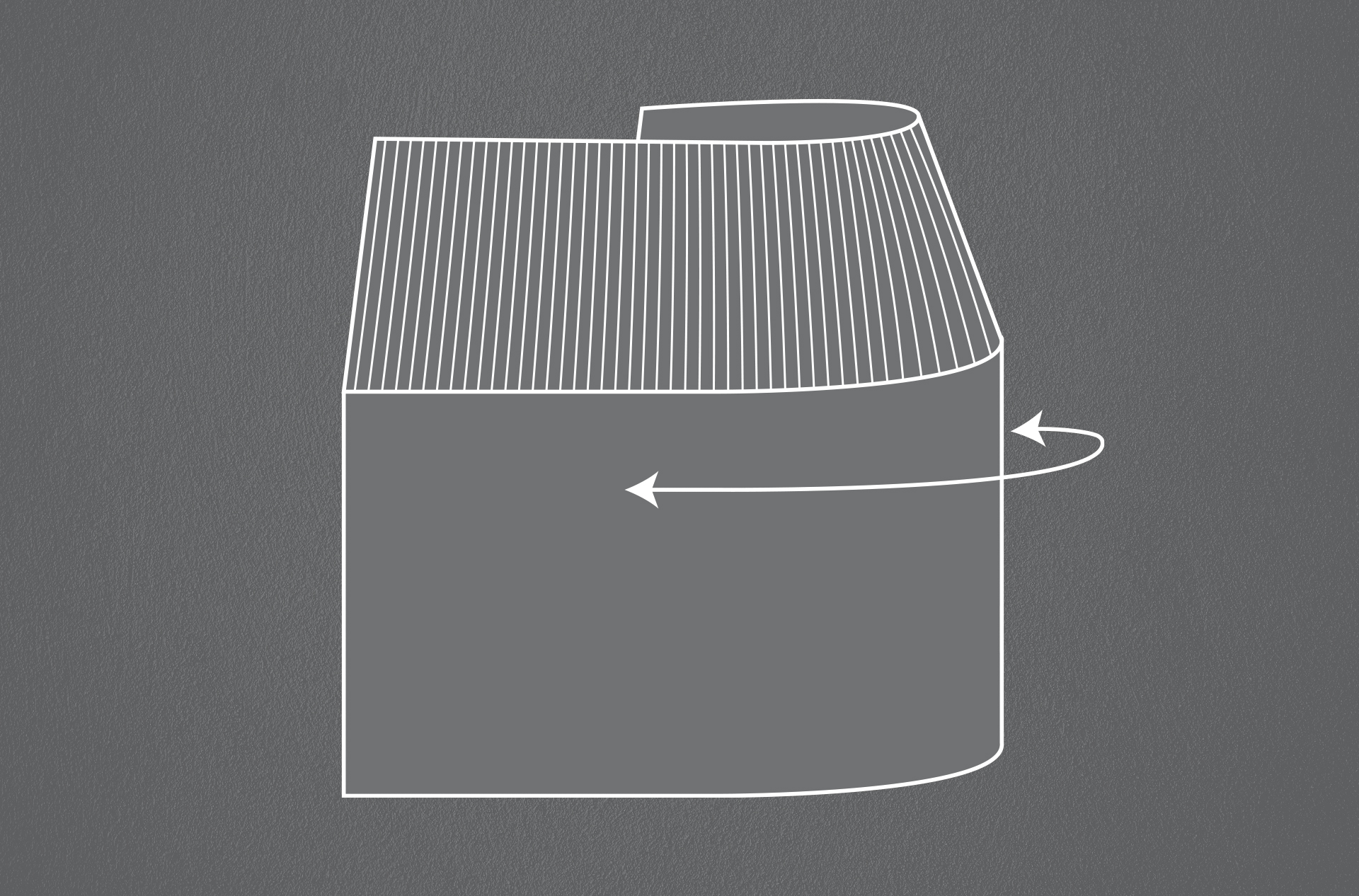

- Solves challenges when processing film at sharp angles

- Optimized for cutting card stock and laminated paper with improved flexibility and durability

- Specially tempered blade body prevents tip chipping and reduces dust or fibrous residue during cutting

- Broad application range reduces the need for multiple blade types, offering greater cost efficiency

Product Applications

| Thickness mm |

Height mm |

Hardness (body) HV |

Hardness (Edge) HV |

Blade Tip Shape | Angle ∠ |

|---|---|---|---|---|---|

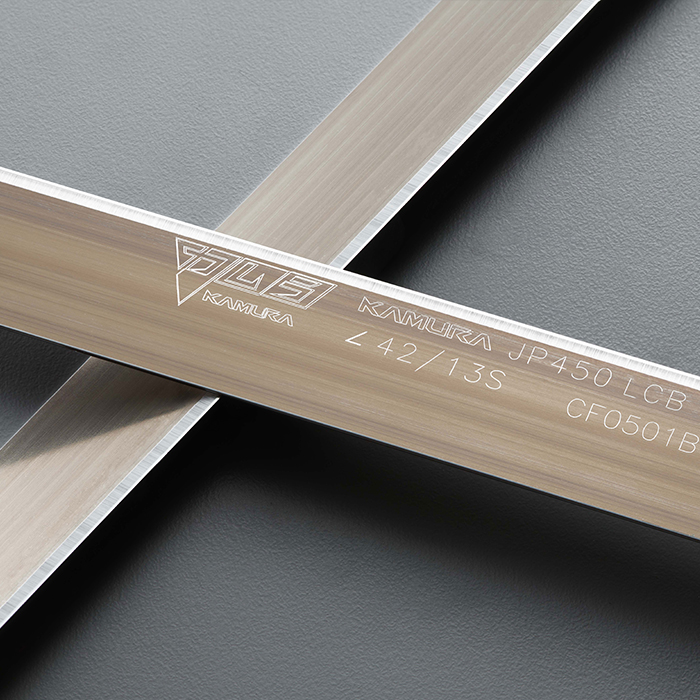

| 0.53 | 23.6 | 340 | 600 | Center Single Bevel | 42 |

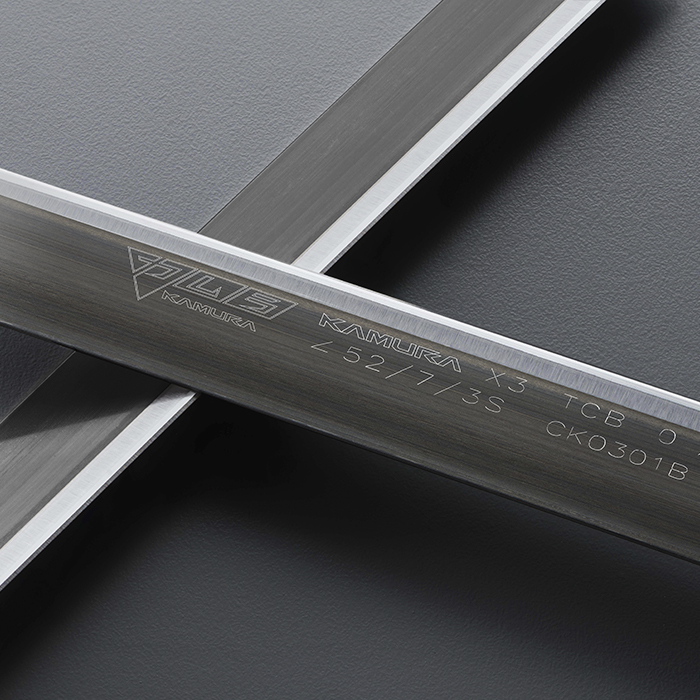

| 0.71 | 23.8 | 380 | 640 | Center Double Bevel | 52 |

| 1.06 | * | 400 | 670 | * | * |

| 1.42 | * | 450 | 700 | * | * |