Plastic Creasing Rule

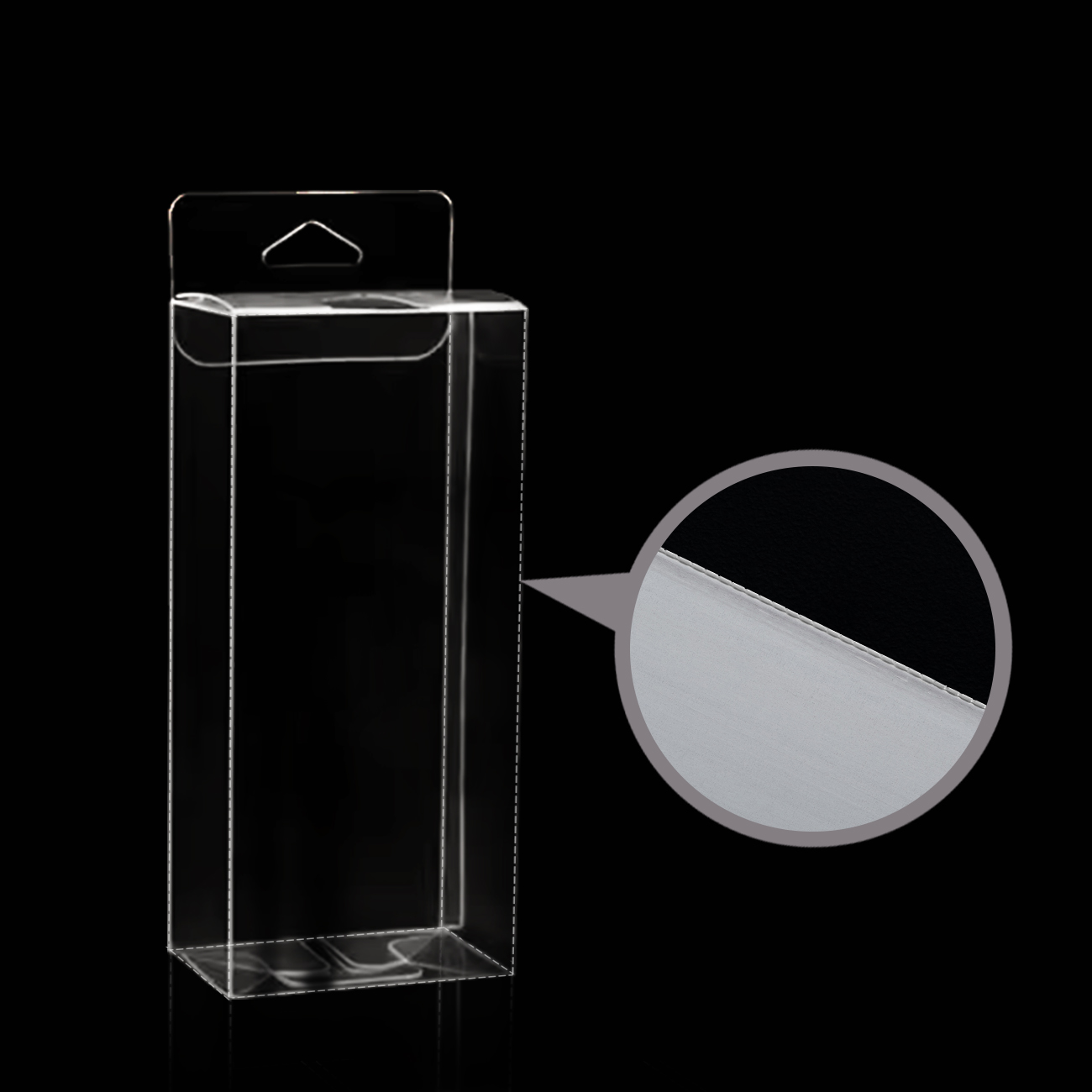

The Creasing Rule for plastic boxes is a specialized die-cutting component tailored for materials like PVC, PET, and PP.

It plays a key role in shaping precise fold lines during the production of plastic folding boxes.

By applying controlled pressure, this rule produces sharp, consistent creases that enhance foldability without causing cracks or deformation. The result is a clean, reliable, and high-quality package that maintains its shape and appearance.

Perf-Creasing Rule vs Regular Creasing Rule

-

Perf-Creasing Rule

- Crease Clarity: Sharp, well-defined lines with clean edges and crisp corners; minimal shifting during folding.

- Forming Stability: High consistency in crease lines ensures precise folding and straight, aesthetically pleasing box shapes after assembly.

- Visual Finish: Optional groove or textured designs enhance the appearance, giving the packaging a premium, detail-rich look.

- Applications: Ideal for high-end packaging such as electronics, cosmetics, gift boxes, and other products requiring a refined presentation.

-

Regular Creasing Rule

- Crease Clarity: Less defined; crease lines may shift or develop whitening marks.

- Forming Stability: Low; prone to misalignment or bending during folding.

- Visual Finish: Basic appearance with no enhanced surface texture or design.

- Applications: Suitable for mass production of food packaging, daily-use product boxes, and other cost-sensitive items.

| Thickness mm |

Height mm |

Hardness HV |

Blade Tip Shape |

|---|---|---|---|

| 0.71 | 16.00-50.00 | 320 | perfC |

| * | * | 340 | * |

| * | * | 380 | * |

| * | * | 400 | * |

| * | * | 450 | * |